INDUSTRIES & SPECIALIZATIONS

CMW GLOBAL

CMW Global delivers precision engineering solutions to the world's most demanding industries. Built over the last 50 years, our comprehensive certification portfolio—including NADCAP, NAVSEA, ASME "U" and National Board "R"—validates our capability to manufacture and repair mission-critical equipment, including complex pressure-rated systems that demand absolute reliability. Whether your application demands naval-grade specifications, pressure vessel standards, or specialized metallurgy, CMW Global has the certifications, experience, and capabilities to deliver solutions that exceed expectations. Our four decades of engineering excellence translate into reliable partnerships across industries where precision matters most.

Advanced Materials Expertise

We specialize in working with high-grade alloys and specialized materials engineered for extreme conditions:

- Corrosion Resistance – Materials that withstand harsh chemical environments and marine conditions

- Abrasion Resistance – Durable solutions for high-wear applications and industrial processes

- High Temperature Performance – Alloys capable of maintaining integrity under extreme thermal stress

This materials expertise, combined with our precision manufacturing capabilities, enables us to serve clients across diverse industries where performance, safety, and reliability are non-negotiable.

Your Industry, Our Expertise

Whether your application demands naval-grade specifications, pressure vessel standards, or specialized metallurgy, CMW Global has the certifications, experience, and capabilities to deliver solutions that exceed expectations. Our five decades of engineering excellence translate into reliable partnerships across industries where precision matters most.

AEROSPACE & DEFENSE

Our Naval and Aerospace Defense customers look to CMW when reliable quality, budget and on-time delivery are critical. They want to leverage our vast supply chain and use our advanced manufacturing capabilities to increase their capacity. Or if they are challenged with design-to-build projects requiring hands-on customer interaction and dedicated engineering problem solving.

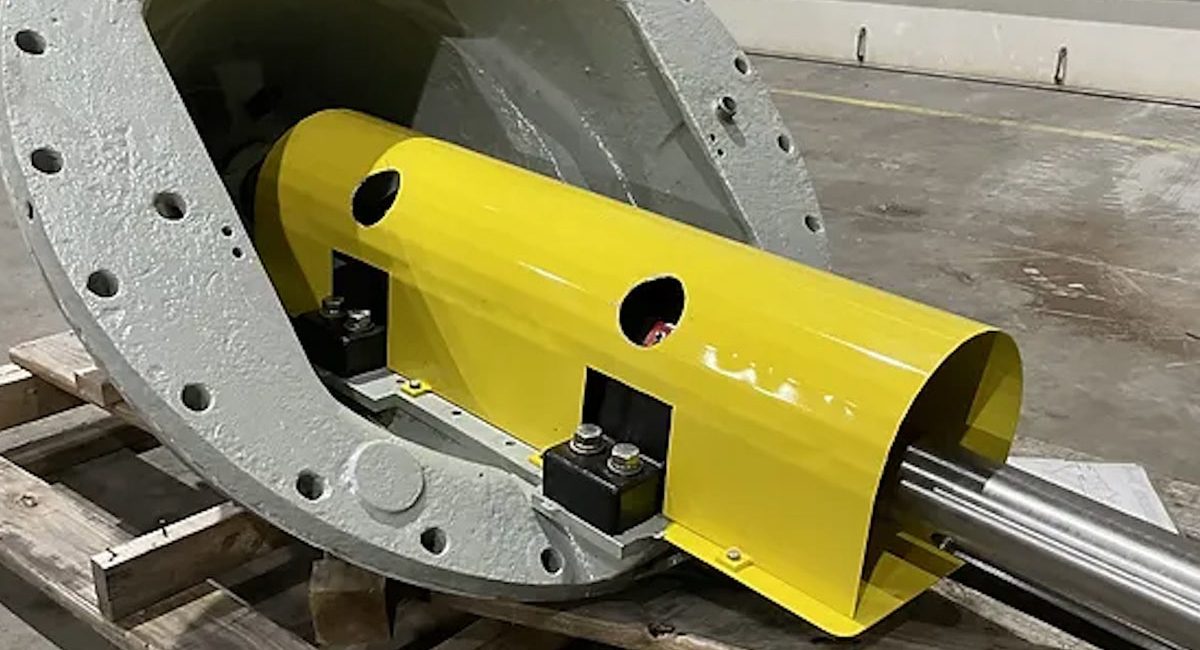

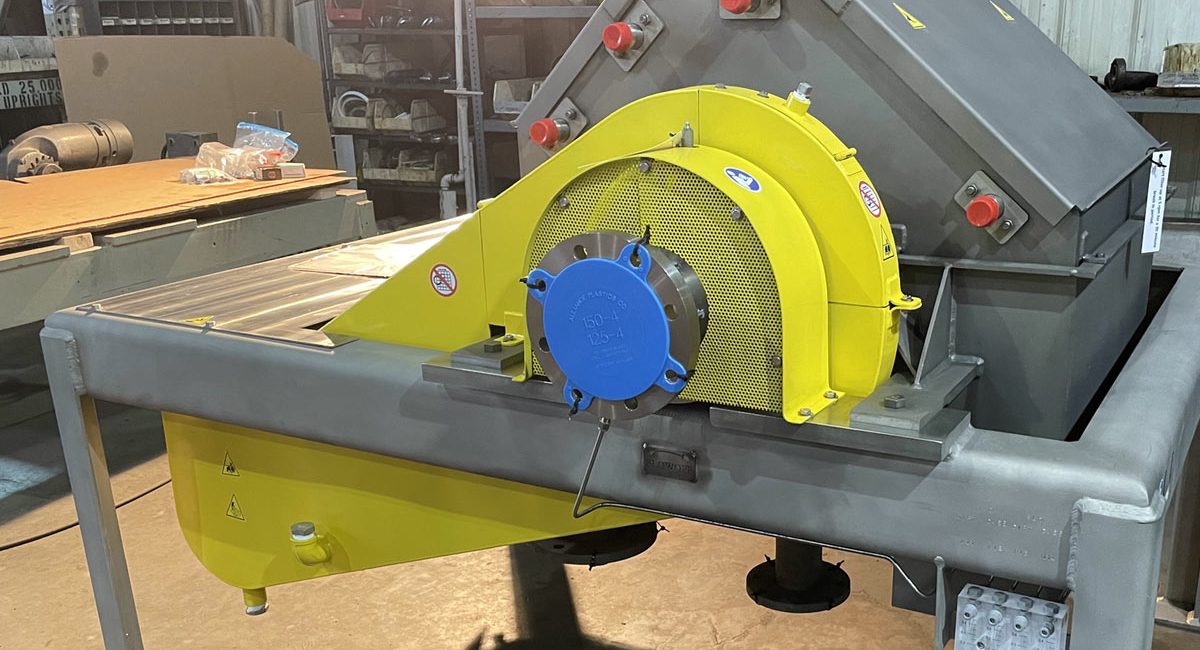

PULP & PAPER

With over 40 years of specialized Pulp & Paper equipment experience, CMW Global delivers precision solutions that keep your operations running at peak performance. We build new equipment and repair existing components across the full spectrum of Pulp & Paper machinery, including tanks, agitators, reactors, dryers, columns, pumps, and centrifuges.

CHEMICAL

As an expert manufacturer with deep experience and advanced capabilities, CMW Global services your critical components to meet your exact temperature, corrosion, and pressure specifications. We build new equipment and repair existing components across the complete range of chemical processing machinery, including tanks, agitators, reactors, dryers, columns, pumps, and centrifuges.

CONTRACT MANUFACTURING

We provide scalable, high-quality manufacturing solutions to various industries, delivering manufacturability improvements and design validation through our extensive fabrication and machining experience. We finalize designs and utilize our comprehensive manufacturing capabilities to bring your concepts to reality.

NUCLEAR

Our Nuclear customers look to CMW when challenged with design-to-build projects requiring hands-on customer interaction and dedicated engineering problem solving, frustrated with late deliveries, constant budget overruns and need a reliable solution, facing a long and expensive lead time from the OEM, or looking to improve their supply chain and establish a relationship with a competent partner.

POWER GENERATION

We provide expertise in the manufacturing, refurbishment, and repair of critical components that keep the power flowing: Pressure Vessels, Piping Systems and Components, Turbine Components, Heat Exchangers and Cooling Systems, Welded Assemblies, including new fabrication and repairs to existing ASME-coded vessels.

PHARMACEUTICAL

As an expert manufacturer with deep experience and advanced capabilities, CMW Global services your critical components to meet your exact temperature, corrosion, and pressure specifications. We have the manufacturing expertise to build new equipment and repair existing components across the complete range of pharmaceutical processing machinery, including tanks, agitators, reactors, dryers, columns, pumps, and centrifuges.

MINING

With extensive industrial pump repair experience, CMW Global employs specialized weld repair practices that minimize heat distortion and ensure optimal component integrity. Our advanced methods for stress-relieving post-weld areas enable pump casings to be reassembled and reused with confidence. These techniques provide the ability to refurbish worn components versus purchasing new replacements from original equipment manufacturers (OEMs).

We deliver across industries that demand excellence. From precision aerospace components to heavy industrial assemblies, Carver Machine Works serves manufacturers who can’t afford compromise. Our clients include: