How Does Dye Penetrant Testing Confirm Sound Welds?

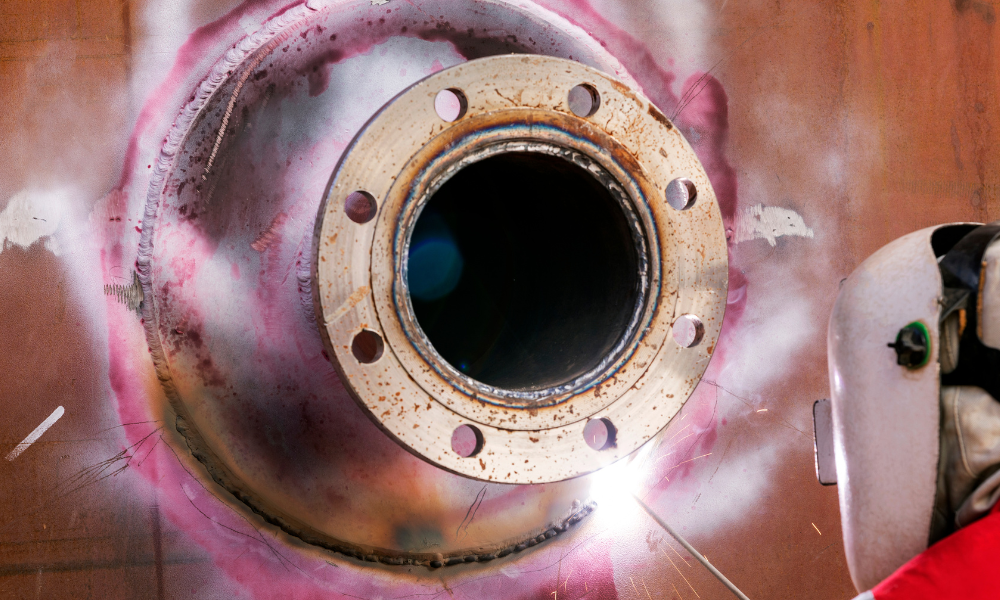

In the world of precision manufacturing and welding, ensuring the integrity of every weld is not just important, it’s mission-critical. At Carver Machine Works (CMW Global), where we serve industries ranging from aerospace and defense to pressure vessel fabrication, the reliability of our welds can mean the difference between safe operation and catastrophic failure. This is where dye penetrant testing becomes an invaluable tool in our quality assurance arsenal.

Dye penetrant testing, also known as liquid penetrant inspection (PT), is one of the most widely used non-destructive testing methods for detecting surface-breaking defects in welds and other manufactured components. As a NADCAP-certified facility with in-house Level 1 and 2 capabilities in penetrant testing—with access to Level 3 services for VT, PT, Ultrasonic Testing (UT), Radiographic Testing (RT), and Magnetic Particle Testing (MT)—CMW Global understands the critical role this inspection method plays in confirming weld quality across diverse applications.

What Types of Weld Defects Can Dye Penetrant Testing Detect?

Dye penetrant testing excels at identifying surface-breaking discontinuities that could compromise weld integrity. The method is particularly effective for detecting defects that open to the surface of the material, making it an essential complement to our comprehensive welding quality control processes.

Common weld defects revealed by penetrant testing include:

Cracks: Whether caused by solidification, hydrogen embrittlement, or thermal stress, surface cracks are the most critical defects penetrant testing can identify. These include hot cracks that form during solidification and cold cracks that develop after the weld has cooled. Even extremely fine surface cracks invisible to the naked eye can be revealed through penetrant testing.

Porosity: Surface-breaking gas pockets or voids that form during the welding process are readily identified through penetrant inspection. While subsurface porosity requires other NDT methods, any porosity that breaches the surface will trap penetrants and create visible indications during inspection.

Incomplete Fusion: Areas where the weld metal fails to completely fuse with the base material or between weld passes show up clearly with penetrant testing. This is particularly important in multi-pass welds where each layer must bond completely to the previous one.

Undercut: This groove melted into the base metal at the toe of the weld creates a stress concentration point. When an undercut is deep enough to create a surface discontinuity, penetrant testing will reveal its extent and severity.

Overlap: Weld metal that flows over the surface without proper fusion creates a stress riser and potential crack initiation site. Penetrant testing identifies these surface irregularities that might otherwise be missed during visual inspection alone.

Grinding Cracks: During weld preparation or finishing operations, excessive grinding can introduce surface cracks that penetrant testing readily detects. These are particularly concerning because they may not be visible to the naked eye.

Weld Toe Cracks: Stress concentrations at the junction between the weld and base metal can lead to crack initiation, especially in fatigue-loaded applications common in aerospace and pressure vessel work.

For CMW Global’s work with critical components in aerospace, nuclear, and ASME-coded pressure vessels, identifying these defects before parts enter service is not optional. It’s a fundamental requirement performed under our ISO 9001 and AS9100-certified quality management systems.

How Does the Dye Penetrant Process Work Step-by-Step?

The effectiveness of dye penetrant testing relies on a carefully controlled process that leverages capillary action to draw penetrant into surface-breaking defects. At CMW Global, our certified technicians follow stringent procedures that ensure consistent, reliable results across all applications.

Step 1: Pre-Cleaning and Surface Preparation

Success in penetrant testing begins with proper surface preparation. The test surface must be completely clean and free from contaminants that could prevent penetrant from entering defects or create false indications. This critical first step involves removing oil, grease, dirt, scale, welding flux, spatter, and any other surface contaminants.

For welded components, this may involve solvent cleaning, alkaline cleaning, or even light abrasive cleaning, though care must be taken not to close up defects through excessive mechanical working of the surface. The surface must be completely dry before penetrant application. Any moisture trapped in defects will prevent penetrant entry and lead to missed indications.

Step 2: Penetrant Application

Once the surface is properly prepared, the penetrant is applied to completely cover the inspection area. Penetrant can be applied through several methods including spraying, brushing, or immersion, depending on the size and configuration of the part being inspected. The penetrant is formulated with very low surface tension, allowing it to flow into the finest surface openings through capillary action.

At CMW Global, we use both visible dye penetrants and fluorescent penetrants depending on application requirements and sensitivity levels needed. The choice between visible and fluorescent penetrant depends on factors including the inspection environment, required sensitivity level, and customer specifications.

Step 3: Dwell Time

After application, the penetrant must remain on the surface for a specified dwell time, which is typically 5 to 30 minutes depending on the penetrant system, material, and expected defect types. This dwell time allows the penetrant to be drawn into surface-breaking defects by capillary action. Larger or tighter defects may require longer dwell times for adequate penetration.

Temperature also affects penetrant performance. While room temperature is typical, both excessively cold and hot conditions can impact penetrant viscosity and therefore its ability to enter defects. Our controlled facility environment ensures optimal conditions for consistent penetrant testing results.

Step 4: Excess Penetrant Removal

Once adequate dwell time has elapsed, excess penetrant must be carefully removed from the surface while leaving penetrant trapped in any defects. This is one of the most critical steps because over-cleaning can remove penetrant from defects, while under-cleaning creates background that obscures indications.

The removal method depends on the penetrant type. Water-washable penetrants can be rinsed directly with water. Solvent-removable penetrants require wiping with clean cloths followed by careful solvent application on a cloth, never spraying solvent directly onto the part. Post-emulsifiable penetrants require application of an emulsifier that makes the penetrant water-washable.

Step 5: Developer Application

After the surface is cleaned and dried, a developer is applied. The developer acts as a blotting agent, drawing penetrant out of defects and spreading it on the surface to create a visible indication that is larger and easier to interpret than the actual defect. Developer can be applied as a dry powder, water-suspended solution, or solvent-suspended aerosol depending on the penetrant system and application requirements.

The developer creates a white coating that provides contrast for visible dye (red) penetrants or a background for fluorescent penetrants under UV light. Development time typically ranges from 10 to 30 minutes, during which the blotting action occurs and indications become fully visible.

Step 6: Inspection

The final step involves systematic inspection of the entire test area under appropriate lighting conditions. For visible dye penetrants, inspection is performed under white light with minimum intensity of 100 foot-candles. For fluorescent penetrants, inspection occurs under UV-A (black light) radiation with minimum intensity of 1,000 microwatts per square centimeter in a darkened environment with ambient light below 2 foot-candles.

Our Level 2 and Level 3 certified inspectors evaluate each indication against acceptance criteria specified in applicable codes and standards, such as ASME Section VIII for pressure vessels or aerospace specifications for defense components. They distinguish between relevant indications (actual defects), non-relevant indications (false indications from surface conditions), and background noise.

Step 7: Post-Cleaning

After inspection is complete and results are documented, the test surface is cleaned to remove all developer and penetrant residues. This is especially important when the component will undergo subsequent coating, heat treatment, or welding operations. Any remaining chemicals could interfere with these processes or cause corrosion in service. For components going into critical service, particularly in aerospace or nuclear applications, thorough post-cleaning ensures no chemical residues remain that could affect long-term material performance.

What Are the Limitations of Dye Penetrant Testing for Weld Inspection?

While dye penetrant testing is an extremely valuable inspection method, understanding its limitations is essential for developing comprehensive quality control strategies. At CMW Global, we combine penetrant testing with other NDT methods to provide complete inspection coverage for critical components.

Surface-Only Detection

The most significant limitation of penetrant testing is that it can only detect defects that break the surface. Subsurface defects, no matter how large or critical, will not be revealed by penetrant inspection. This includes subsurface porosity, incomplete penetration at the root of a weld, subsurface slag inclusions, and lack of fusion that doesn’t extend to the surface.

For welded components in critical applications such as ASME-coded pressure vessels or aerospace structures, this means penetrant testing must be supplemented with volumetric examination methods like radiographic testing (RT) or ultrasonic testing (UT) to detect internal discontinuities. CMW Global maintains in-house Level 3 capabilities in both RT and UT specifically to address this limitation.

Material Limitations

Penetrant testing is not suitable for porous materials such as unglazed ceramics or certain powder metallurgy parts. The penetrant will absorb into the entire material rather than just entering defects, making interpretation impossible. While this is rarely an issue for welded metallic components, it’s important to understand when specifying inspection methods.

Surface Condition Requirements

The surface condition directly affects penetrant testing reliability. Rough or heavily scaled surfaces make it difficult to remove excess penetrant cleanly, leading to background noise that can obscure small indications. Similarly, surface coatings, paint, or platings must be removed before inspection, which may not always be practical for in-service inspections.

For as-welded surfaces with significant weld ripples or spatter, the rough texture can trap excess penetrant and create false indications. In these cases, light grinding or machining of the weld surface may be necessary for reliable inspection, though care must be taken not to close up surface defects in the process.

Sensitivity to Surface Preparation

Improper cleaning is one of the most common causes of unreliable penetrant testing results. Oil, grease, or other contaminants can prevent penetrant from entering defects. Conversely, certain cleaning methods—particularly aggressive mechanical cleaning—can close up defects or smear metal across crack openings, preventing penetrant entry.

Environmental Considerations

Many penetrant systems contain chemicals that require proper handling, storage, and disposal. Flammable solvents, skin irritants, and environmental regulations must be managed appropriately. Additionally, temperature extremes can affect penetrant performance, making field inspections challenging in some environments.

Defect Orientation Sensitivity

While penetrant testing is generally good at detecting defects regardless of orientation, very tight cracks that are closed under residual stress may not allow penetrant entry. Some cracks that would be detected under load may close when the component is unstressed during inspection.

When Should Dye Penetrant Testing Be Combined with Other NDT Methods?

At CMW Global, our comprehensive NDT capabilities, including in-house PT, VT, UT, RT, and MT, allow us to design inspection programs that address the specific requirements of each application. The decision to combine penetrant testing with other methods depends on several factors.

Critical Pressure-Retaining Applications

For ASME-coded pressure vessels, which represent a significant portion of CMW Global’s fabrication work, penetrant testing is typically combined with radiographic or ultrasonic examination. While PT confirms surface integrity and weld contour quality, RT or UT provides volumetric examination to detect internal discontinuities that could lead to failure under pressure.

ASME Section VIII Division 1 and Division 2 codes specify when each examination method is required based on joint category, pressure, temperature, and material thickness. Our National Board “R” stamp and ASME “U” stamp authorizations ensure we implement the correct combination of inspection methods for code compliance.

Aerospace and Defense Components

Aerospace applications demand the highest levels of quality assurance. Components for aircraft, spacecraft, or defense systems typically require multiple NDT methods as specified in detailed inspection plans. Penetrant testing verifies surface condition while other methods examine internal material integrity.

Our NADCAP accreditation for fusion welding demonstrates our capability to meet aerospace industry requirements for combined inspection approaches. Many aerospace specifications require PT on all accessible surfaces combined with RT or UT for critical joints. The specific combination is dictated by the part classification and applicable specifications.

Material-Specific Considerations

For ferromagnetic materials like carbon steel, stainless steel, and many nickel alloys that CMW Global commonly welds, magnetic particle testing (MT) offers an alternative to PT with some unique advantages. MT can detect surface and slightly subsurface defects, making it complementary to penetrant testing.

For non-ferromagnetic materials like aluminum, titanium, and nickel-based superalloys, materials we frequently work with in aerospace applications, PT becomes the primary surface examination method. These materials often require PT in combination with UT for complete inspection coverage.

Complex Geometry Components

Components with complex geometries, internal passages, or limited access areas may require multiple inspection methods to ensure complete coverage. Penetrant testing is excellent for accessible surfaces but may need supplementation with remote visual inspection, ultrasonic testing, or other methods for hidden areas.

For rotating equipment repairs, such as the pump and blower refurbishment work CMW Global performs for pulp and paper and mining industries, PT is typically combined with dimensional inspection, visual examination, and sometimes UT to ensure worn or damaged components are properly restored.

Post-Weld Heat Treatment Considerations

For applications requiring post-weld heat treatment (PWHT), inspection timing becomes critical. Some specifications require PT both before and after PWHT because the thermal cycle can reveal defects that weren’t visible initially or can cause new cracks to form from residual stresses. In these cases, PT is combined with periodic inspections throughout the fabrication process.

In-Service Inspection Programs

For equipment already in operation, penetrant testing is often part of a comprehensive in-service inspection program that includes thickness measurements, corrosion assessment, and fitness-for-service evaluations. PT identifies surface cracking from fatigue, stress corrosion, or other damage mechanisms, while other techniques assess remaining material thickness and internal condition.

Ensuring Weld Quality Through Comprehensive Inspection

Dye penetrant testing remains one of the most valuable tools in the non-destructive testing arsenal for confirming weld quality. Its ability to detect surface-breaking defects with high sensitivity, combined with its versatility across different materials and applications, makes it indispensable for quality assurance in precision manufacturing.

At CMW Global, our four decades of experience in serving demanding industries has reinforced the importance of proper penetrant testing procedures. From our NADCAP-accredited aerospace work to ASME-coded pressure vessel fabrication, we understand that reliable weld inspection requires not just the right equipment and materials, but also properly trained personnel following rigorous procedures.

Our in-house NDT capabilities spanning multiple methods, from penetrant testing to radiography and ultrasonics, allow us to design inspection programs that provide complete confidence in component integrity. Whether we’re fabricating new pressure vessels, repairing critical rotating equipment, or manufacturing aerospace components, penetrant testing plays a vital role in our quality system.

The key to successful penetrant testing lies in understanding both its capabilities and limitations. When combined with proper surface preparation, appropriate penetrant selection, trained inspection personnel, and integration with complementary NDT methods where needed, dye penetrant testing provides reliable confirmation of sound welds that meet the most stringent quality requirements.

For manufacturers working with critical components where weld integrity is non-negotiable, partnering with a fabricator that maintains comprehensive NDT capabilities and the certifications to back them up ensures that quality is built into every project from the start. At CMW Global, that’s not just our promise, it’s the foundation of our reputation built over 50 years of delivering excellence to the world’s most demanding industries.