Five decades of reliable service require a focused mission

The CMW GLOBAL MISSION

Our mission at CMW Global is to add value to our customers through our superior quality, extensive experience, and cost-effective solutions. We strive to enhance and ensure the success of our customers through teamwork, transparency, and effective execution.

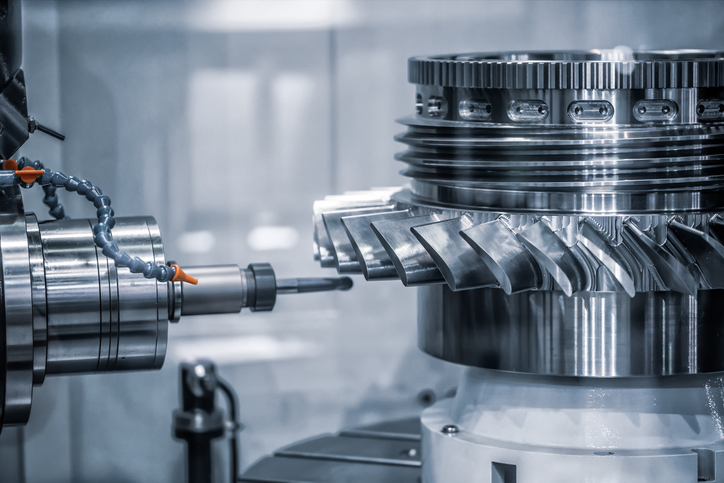

World Class Quality

BACKED BY THE TOUGHEST CERTIFICATIONS

Whether custom metal fabrication or refurbishment of high-value, operation-critical mechanical components, our 4 decades of experience are backed by the certifications you expect and demand for your projects.

ISO 9001:2015 and AS9100D Certified (Quality Management System)

Total quality system & continuous improvement program ensures we consistently meet our customers’ expectations

NADCAP Accredited

Accredited by the National Aerospace and Defense Contractors Accreditation Program

NDT

CMW Global capabilities include: In-house Level 1 & 2 – VT and PT Level 3 – VT, PT, UT, RT and MT

OUR HISTORY

1976

Carver Machine Works (CMW Global) is founded. The founding family incorporates the industrial repair firm whose primary customer is a local phosphate mining and chemical processing facility.

1982

In an effort to sustain and grow Carver Machine Works expanded into the Pulp and Paper industry to diversify the organization’s market base.

1983 – 1993

Carver Machine Works grows its industrial market share throughout the southeastern US by effectively leveraging its expertise developed in repairing and improving industrial rotating equipment performance while decreasing equipment cost of ownership for our customers. Carver Machine Works continues to accumulate extensive technical and dimensional data through its reverse engineering of high-wear, process-critical, industrial processing equipment.

1994

Due to Carver Machine Works’ superior quality and fast response performance, adds their first international customer building titanium processing equipment and distributing this equipment throughout the globe.

1995 – 1998

Carver Machine Works expands its industrial repair services to the Chemical and Petrochemical industries. Developed their ‘build to print’ capabilities and added ASME “U” and National Board “R” designations allowing them to build and repair pressure-rated industrial tanks and heat exchangers.

1999

The founding family divest themselves of the corporation by selling the company to an Employee Stock Ownership Plan.

1999 – 2005

CMW Global continues growth in the Southeastern US within the pulp, Paper, Chemical, and Pharmaceutical markets by adding experienced field Sales Engineers who consult with their customers on cost savings ideas that include extending useful life and repair alternative ideas for maintaining process critical equipment and maximizing the useful life of that equipment.

2005 – 2007

Carver Machine Works expands into the Nuclear Energy, Aerospace, and Defense Industries by implementing an ISO9001 and AS9100-compliant total quality system. CMW adds its first of many degreed engineers to its team.

2007

CMW Global earns the NADCAP (National Aerospace and Defense Contractors Accreditation Program) certification in fusion welding, becoming one of the first NADCAP facilities in the southeastern US.

2008

Carver Machine Works undergoes a 50,000-square-foot facility expansion which significantly increases the size and weight handling capacity while providing improvements in manufacturing process flow efficiencies.

Carver Machine Works accepts its first Naval Defense Contract.

2008 – 2011

CMW Global continues growth within its industrial customer base and experiences significant growth in the Nuclear Energy and Defense sectors by developing strong supply chain partners and creating effective and reliable project integration capabilities.

2012

Carver Machine Works obtains their AS9100 and ISO 9001 certifications further expanding their reach into quality critical, ‘build to print’ market opportunities.

2013 – 2019

Diversified market base growth continues while focusing on internal process improvements and metrics to maximize the company’s quality, on-time delivery, and financial performance.

2020

Carver Machine Works liquidates the Employee Stock Ownership Plan through a management buyout, creating a significantly improved retirement benefit for their team and business structure to support strategic investments in capabilities that enhance the company’s value to their customers.

2022

Carver Machine Works acknowledges its position as an international leader in Aerospace, Defense, or Industrial Manufacturing and rebrands to become CMW Global.

2025

CMW Global celebrates 50 years!