The Precision That Your Project Demands

High Precision Machining And Waterjet Capabilities

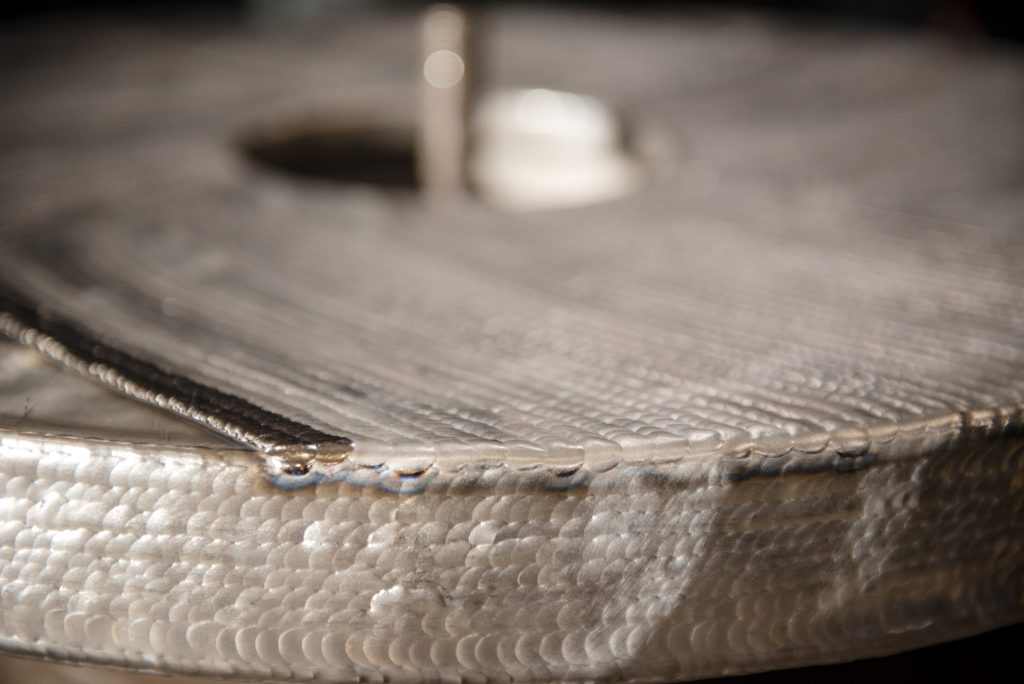

CMW Global leads in precision machining services, delivering world-class solutions and advanced waterjet capabilities for defense, aerospace, and industrial sectors. As technology advances, so do we. Our precision machining shop is powered by a highly skilled team of Master Craftsmen and Mechanical Engineers, bringing over four decades of expertise in advanced manufacturing, stringent quality control, industry certifications, and specialized materials. Whether you require tight tolerances or complex machining challenges, our services ensure superior results for your project.

Precision Machining

Our Equipment Tackles The Most Stringent Tolerances & Machining Challenges

- 3 Horizontal Boring Milles (HBMs) with 4″ to 6″ spindles

- 7 Engine Lathes ranging up to a max swing of 63″ x 312″ overall length

- 3 Vertical Turret Lathes (VTLs) with up to a 79″ swing

- HAAS CNC 3-axis Milling Center

- 2 Manual Milling Center

- OMAX 55100 Waterjet Machine with a 50″ x 100″ x 6-1/2″ thickness cut capacity

- Faro Arm CMM with 6′ swing

See our HAAS CNC Lathe in Action

Your Next Project Will Benefit Greatly From Our World-Class Machining and Waterjet Capabilities including:

A deep knowledge of material properties, manufacturing processes, and industry-specific design requirements from 4 decades of experience working with specialized materials, such as high-strength alloys, super-alloys, and exotic metals.

Certifications and accreditations include ISO 9001 (Quality Management System), AS9100 (Aerospace Quality Management System), NADCAP (National Aerospace and Defense Contractors Accreditation Program), and various military, government, and industrial certifications.

Reliable supply chain management and strict requirements, supplier qualification, material traceability, and inventory control systems.

Stringent quality control including in-process and post-process inspections, to ensure that parts meet the exacting specifications and standards demanded by the project.

Specialized materials expertise: Experience working with a wide range of materials, including high-strength alloys, superalloys, ceramics, and composites, which are commonly used in aerospace, defense, and industrial applications.