CMW Global Offers Innovative Expertise in a Diverse Array of Industries

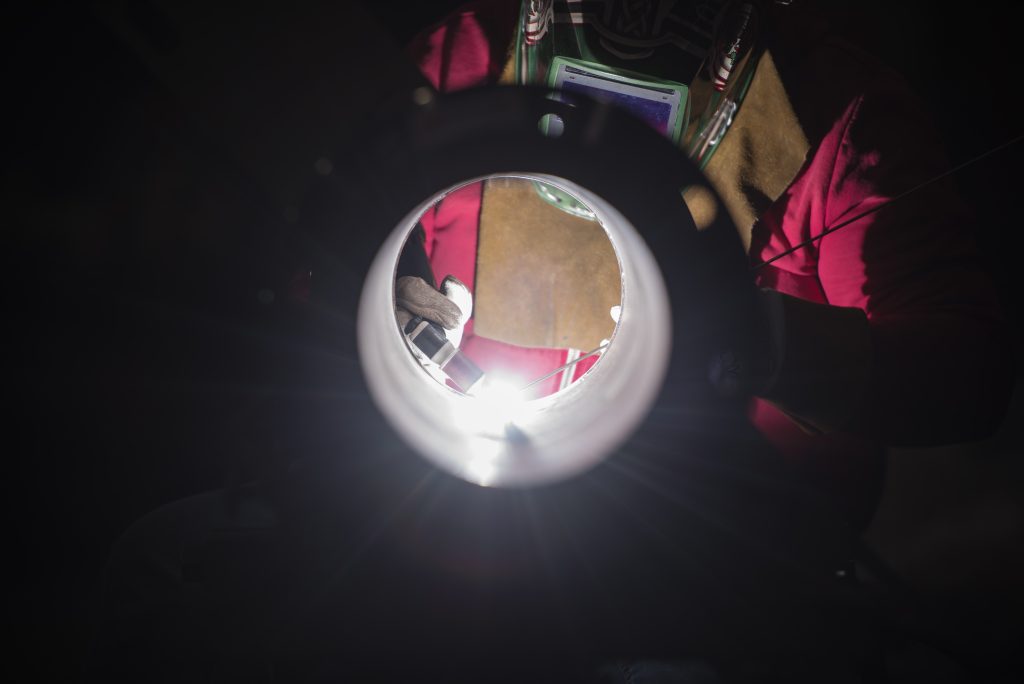

Being a leader in the industry of metal fabrication and machining in a diverse array of industries requires an intricate attention to detail. It requires having top-of-the-line machinery and the skilled craftsmen who know how to position and weld discrete parts so they are crafted within a few thousandths of an inch of accuracy in reference to one another. It requires having machinery that registers 300% straighter than the industrial standards to provide excellence in power and precision for machining enormous pieces.

CMW Global’s work within the important industries of aerospace and defense, nuclear, pharmaceutical, power generation, and more requires meticulous attention to detail, gold-standard equipment, and decades of expertise. While we hold ourselves to the same high standards across industries, we want to highlight each of our areas of expertise to showcase the impact we are making in a diverse array of industries while highlighting the top-of-the line equipment we use to do so.

Our quality certifications, including NADCAP, NAVSEA, ASME “U” and National Board “R”, further solidify our reputation as a world-class fabricator with the skills to both build and repair critical equipment, including equipment that is pressure-rated. The experience CMW Global has in working with high-grade alloys and other exotic materials that provide corrosion, abrasion resistance, and high-temperature capabilities that will extend the life of your equipment, makes us leaders in the world of machining.

You can find CMW Global working on cutting-edge innovations in the following industries:

- Aerospace and Defense

- Pulp & Paper

- Chemical

- Contract Manufacturing

- Mining

- Power Generation

- Pharmaceutical

- Nuclear

How does CMW Global stand out as innovative experts in a diverse array of industries?

CMW Global has almost 50 years of experience fabricating and rebuilding equipment across a variety of industries. This deep experience gives us familiarity and experience with most common OEM names and designs, offering less lead time and expense for your project. We know which machines are best to craft precise pieces, providing parts that are crafted within a few thousands of an inch of accuracy. Simply put, we know what we’re doing, and we do it well. Our ability to machine and weld special materials including Titanium, Hastelloy, duplex, stainless steel, and Inconel immediately separates us from others in the field.

With our superior engineering team, we are able to reverse engineer existing obsolete equipment, saving your bottom line. To add to the experience, unlike ordinary manufacturers, we bring our sales engineers and technical assistance teams onsite to your facility and orchestrate a fleet for pickup and delivery of critical equipment. We promise integrity and responsive action and are readily available to meet the needs or concerns of any of our partners. In the same mindset, we seek long-term partnerships. We don’t think about our client relationships in the scope of a single job. We want to be true partners and know your business inside and out. With our extensive supplier partnerships, we have the ability to offer well beyond our in-house services with the ability to provide coatings, heat treating, and other special processes fit to your needs.

CMW Global’s Gold Standard Equipment

The right machinery is imperative to any business working in the realm of metal fabrication. At CMW Global, we have carefully procured our equipment to meet the exact needs of our clients while maximizing part size capability and part access to hold tight tolerances across large outputs. Working with gold-standard equipment requires a mastered knowledge on cutting parameters and the certifications that come with welding various alloys. Here are just a few of our cutting-edge pieces of machinery that add to our credibility as experts across our diverse array of industries.

Nomura Horizontal Boring Mill

From Japan’s oldest and most experienced manufacturer, the Nomura Horizontal Boring Mill is cast from high grade iron that has been hardened and hand-scraped to perfection. 300% straighter than Japanese Industrial Standards require, the ballscrews, gears, bearings, and internal components go well beyond the standard of compliance, making it perfect for use across a diverse array of industries. This high grade of equipment helps to create parts with full and complete accuracy above any normal standard. The equipment you use should be a testament to your commitment to success, which is why we go above and beyond to utilize only the best machinery inhouse. With 78.8’’ horizontal cross, 55.1’’ longitudinal in / out, 60’’ vertical up / down, and 19.7’’ spindle measurements, you can see why this piece is essential for large precision machining.

Lucas Horizontal Boring Mill

This popular tool meets well above industry standards by providing high performance machining with maximum utilization of accessories. It is extremely versatile and can machine workpieces up to 20 tons in weight, making it perfect for larger pieces. At 114’’ horizontal cross, 84’’ longitudinal in / out, 72’’ vertical up / down, and a 6’’ spindle, this is perfect for providing precision to larger pieces, making it essential for our work across many industries, especially the aerospace industry.

Union Horizontal Boring Mill

Manufactured by WMW Union, our horizontal boring mill was manufactured according to ISO 9001:2008 standards and has been certified by TUV. With 63’’ horizontal cross, 56’’ longitudinal in / out, 47’’ vertical up / down, and 4’’ spindle, this piece allows for mastery in precision and detail work.

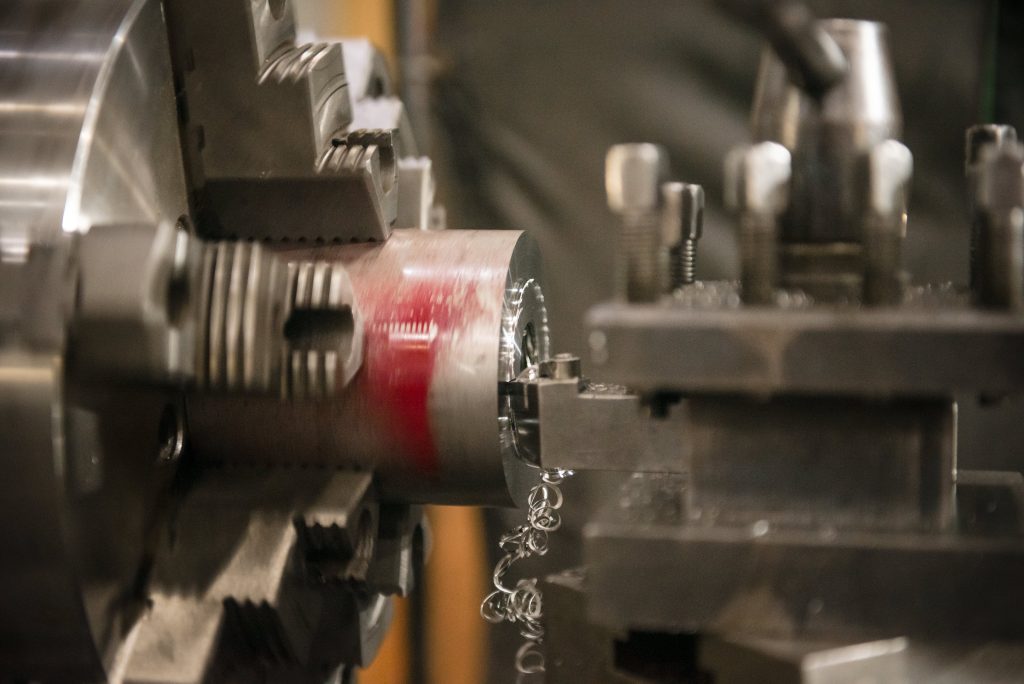

Stanko Lathe

One of the most useful and necessary machines in our shop, the Stanko Lathe is made for cutting with extreme precision with its grounded and stabilized steel bed. With sealed ball bearings on its spindle, it has the capabilities to cut ⅛’’ into mild steel and dust a few tenths, making it versatile and precise. With 40’’ chuck diameter, 63’’swing over bed, 50’’ swing over cross slide, 312’’ OAL, it can handle a wide variety of sizes creating the same trusted precision on each piece.

HASS 45L CNC Lathe

This lathe has an 18’’ chuck, 34.5 swing over bed, 25.5 swing over cross slide, 80’’ OAL, and 12 station turret designed from the ground up to provide flexibility, extreme rigidity, and high thermal stability. The ST-45L is a long-bed, big-bore lathe that offers the best performance in its class including extra-long work envelope, fully programmable servo tailstock, 12-station bolt-on turret with hydraulic clamping, and a large spindle nose and spindle bore.

The CMW Global Team

Before we dive deeper into our industry footprint we need to highlight our expert team. Even the best machinery is nothing without an expert staff and our engineers and craftsmen get the most out of each piece of machinery as some of the best in their field. Our facility contains 72,000 square feet of manufacturing space with 24-feet under hook and the ability to lift 30 tons. Our space and top-tier equipment attract experienced machinists to our ranks. You don’t get an expert team without committing to them in the same way they commit to you. We believe that everyone should be respected and listened to, and that translates in all of our interactions, making our team another component in our formula for success.

A deeper dive into our industry footprint across a diverse array of industries

Aerospace and Defense

When reliable quality, budget, and delivery are imperative, our aerospace and defense customers look to CMW Global for our expertise. Our vast supply chain and integration capabilities can meet the complicated professional standards of the aerospace and defense industry. With machines such as our Lucas Horizontal Boring Mill, our machinery can handle the large and heavy metal working required within this industry with ease. The precision of the Nomura Boring Mill, Stanko Lathe, and more than a dozen other pieces of machinery allows for the precise specifications needed by this industry. They allow us to weld discrete parts within a few thousandths of an inch of accuracy. Our dedicated engineers’ ability to problem solve and step up to meet the highest design standards and our customer interaction standards also contribute to our leadership within the worlds of aerospace and defense.

Pulp & Paper

We have over 40 years of experience working in the pulp and paper equipment industry. This extensive history in the field, along with our certifications, has provided us with expertise in building or repairing tanks, agitators, reactors, dryers, columns, pumps, and centrifuges that operate everything from pulpers to bleach tanks. With our Nomura Horizontal Boring Mill providing results 300% straighter than Japanese Industrial Standards require, the ballscrews, gears, bearings, and internal components go well beyond the standard of compliance, allowing for the extreme precision needed for metal fabrication, machining and reverse engineering within the realms of pulp & paper.

Chemical

Our expert manufacturers can service your critical components to meet requirements for specific temperature, corrosion, and / or pressure specifications. Our HAAS 45L CNC Lathe plays a big part in the creation of these pieces, as it is designed from the ground up to provide flexibility, extreme rigidity, and the high thermal stability needed when fabricating metal for the chemical world.

Contract Manufacturing

We utilize our extensive expertise in manufacturing capabilities to bring your concepts to reality. We provide scalability and high-quality manufacturing concepts to aid in the finalization and execution of your design concepts. By working closely with our clients and attracting expert craftsmen to our team, we are able to create even the most intricate of designs with the highest precision and quality.

Mining

We have extensive industrial pump repair experience and skilled weld repair practices and experience that can limit heat distortion. Our methods of repair provide the ability to refurbish worn components rather than ordering new replacements from the original equipment manufacturer (OEM) at a considerable cost savings.

Power Generation

We provide expert manufacturing, refurbishment, and repair of critical components that keep the power flowing in the realm of power generation as well as in the diverse array of industries we have our footprint in. We offer the experience and capabilities to service your critical components to your specific temperature, corrosion specifications, and pressure specifications regarding pressure vessels, piping systems, turbine components, heat exchangers, and cooling systems. With the precision and detail work offered by our Union Horizontal Boring Mill and over twenty other pieces of fabrication equipment, we are an industry leader in new fabrication and repairs to existing ASME-coded vessels.

Pharmaceutical

With our ability to build or repair the materials necessary for the meticulous precision that comes with the pharmaceutical industry, CMW Global meets the top industry standards for producing and repairing quality pieces of machinery in the pharmaceutical industry. Our footprint in the pharmaceutical industry expands to tanks, agitators, reactors, dryers, columns, pumps, centrifuges, and more.

Nuclear

Our nuclear customers look to CMW Global when challenged with design-to-build projects requiring hands-on customer interaction and dedicated engineering problem solving. If your team is frustrated with late deliveries and constant budget overruns, is in need of a reliable solution, is facing a long and expensive lead time from the OEM, or is looking to improve their supply chain by establishing a relationship with a competent partner, we are here to meet your needs. CMW Global has almost 50 years of experience fabricating and rebuilding equipment across a variety of industries. This deep experience gives us familiarity and experience with most common OEM names and designs, offering less lead time and expense for your project.

Thanks to our expert craftsmen, gold-standard equipment, and decades of experience providing metal fabrication, CMW Global is the lead contender in a vast array of industries amongst the machining world. Continue to follow along with our blog series to understand more about our footprint in each of the industries we are working in and the equipment we bring to the table that helps solidify our place as the leading contenders in each field.